Karex AGM 2018 Highlights

Difference Gloves vs

Condom

Class I Medical Devices

A Class I medical device are those devices

that have a low to moderate risk to the patient and/or user. Today, 47% of

medical devices fall under this category and 95% of these are exempt from the

regulatory process. If a device falls into a generic category of exempted Class

I devices, a premarket notification application and FDA clearance is not

required before marketing the device in the U.S. However, the manufacturer is

required to register their establishment and list their generic product with

FDA. Examples include enema kits, elastic bandages, manual stethoscopes, and

bedpans.

Class II Medical Devices

Class II medical devices are those devices

that have a moderate to high risk to the patient and/or user. 43% of medical

devices fall under this category. Most medical devices are considered Class II

devices. Examples of Class II devices include powered wheelchairs and some

pregnancy test kits.

Class III Medical Devices

Class III medical devices are those devices

that have a high risk to the patient and/or user. These devices usually sustain

or support life, are implanted, or present potential unreasonable risk of

illness or injury. They represent 10% of medical devices regulated by the FDA.

Examples of Class III devices include implantable pacemakers and breast

implants

Gloves

Medical Classification – Class I

Manufacturing Process

1. Dipping

2.

Boxing

-

Glove Manufacturers do not need

to test all their products.

-

Instead, they do sampling to

check for pinholes. If the glove passes the test, it can be used for medical

purposes. Otherwise, it goes for general usage.

-

Glove Manufacturers can

translate cost prices to customers every month.

Condom

Medical Classification – Class II

Manufacturing Process

1.

Dipping

2.

Testing

3.

Casing

4.

Boxing

-

For condoms, I can’t say that

there are some holes on this one and the other is perfect, because there is

only one usage for it. And you cannot say since the US is paying more, then I

give them a better quality while for Africa, I give them all the rejects. So,

each single condom must be tested and certified hole-free.

-

Because of its Medical

Classification – Class II, any changes to the manufacturing process need to be

validated.

-

Condom prices hardly change

because of its competitiveness with other manufacturing player

-

Price Celling from certain

countries

Competitive Advantage

Various Sizing

Bespoke “Perfect fit” condoms with

variations of 10 lengths, nine widths and 60 sizes.

To make sure one fits, customers only need

to download an online ruler called “FitKit”, measure and enter their size to

the website to get the size code.

Other Player: 2-3 Sizes

Automation

2021 plan to switch 80% processes to

Automation

20% is automated currently, 40% Manpower

are from Testing Segment, had cut down approx. 300 employees, aim to cut down

to approx. 1500 employees, currently stands at approx. 2800 employees.

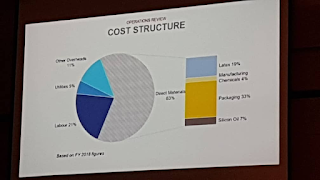

21% Labour Cost are expecting a drop till

10-12% easily after 2021 automation

Other Player: 90% Manual Processes

Karex builds its own machines in order to

have the flexibility advantages in production. Able to weld and build own

machines in-house cope with customer demands.

Latex Compounding

Form Karex Polymers Limited (Thailand)

Karex is improving latex processes in-house

to optimize latex volatile prices, storage of latex during wintering month.

Innovation

Ultra-thin technology able to compete with

other players who having thin condoms.

Players in Industry

Guangzhou Daming United Rubber Products –

World thinnest Latex Condom “Aoni” 0.035-0.039 millimeters

Sagami Rubber Industries – World thinnest Polyurethane condom “Sagami 001” 0.013-0.019 millimeters (yet to compete)

Yearly Capex:

RM20million

Last 5 years, mainly on facilities, and

automation.

Moving 5 years, mainly focusing on

automation

Risk

USD Low

Brent Oil High

Latex Price High

Silicon Oil High

Licensing fees of OBM listing in new

countries

Client need at least 1-2 Years for new

product listing and certification

Challenge

2018 USD sliding from 4.3-3.9 vs MYR

2018 Brent Oil went up from USD 40-70 per

barrel

2018 Latex Price volatile between RM6-RM4

per kg

2018 Silicon Oil USD 4.5-7.5

Tender

Tender to Institutional buyers such as

United Nation Population Fund (UNFPA), United State Agency for International

Development (USAID), Population Service International (PSI), Marie Stopes

International (MSI), John Snow Inc (JSI) and Crown Agents International

Limited

Currently Tender Business covering 50% of

the business looking to continue slides in future mainly due to Global

Government cutting spending on HIV Prevention, to reserve and invest in own

country.

Commercial

Manufacture condoms for customers such as

Ansell Limited (Lifestyle brand), Reckitt Benkiser, PLC (Durex brand), Line One

Laboratories Inc, (Trustex brand)

Consolidation in the industry is being

seen, as a lot small players are throwing condom prices to have healthy balance

sheet and wait for big players acquiring.

OBM

Manufacture condoms under own brands namely

“Carex”, “INNO” and “One”.

Current: 15% Revenue

Target: 30% Revenue by 2022

Main Market : US, UK

Current profit still breakeven, and will

not have any in near 1-2 years, Karex is looking at branding, awareness,

footprint across the world as the world is moving to discountal modal,

supermarket tends to only reserve 2-3 Condom brands in their supermarkets.

Launched new flavor “Nasi Lemak”, “Teh

Tarik” and etc past few months, and had been receive a lot of awareness, “Free

Marketing with cheap cost”. The cost of “Nasi Lemak” flavor is only RM50,000

hence, it boost its brand awareness throughout social media, newspaper, blogs.

Karex is tapping on global social media

trend to engage Social Media Influencer as ambassador such as “Jinnyboy”,

“Namewee” and etc.

Karex own brand “One” is saving costing by

using online platform by having own online store, and listed in Taobao.com,

Amazon.com and coming up in Walmart.com

Opportunity

There are still many countries to penetrate

into for their OBM.

Asian market

has a focus on thickness, preferring their condoms to feel as au naturel as

possible. But North American markets, don’t mind sacrificing a little thickness

in the name of safety.

Lubricants

Karex is

transforming from a condom-centric business into a broader sector called

“sexual wellness”.

While condoms

remain as the company’s main revenue generator, Karex is expanding into other

medical products such as lubrication gels, probe covers and catheters.

Current production: 5 Billion

To produce six billion condoms by next year

and one key element to achieving that is automation in its manufacturing

plants.

Some Questions

and Answers from Shareholders

Why “One”

Brand?

Unique young

brand, young customer based, they never go to advertisement and newspaper for

marketing, we are using crowd sourcing strategy on our online platform to allow

customers to vote, request their flavors, size and etc. We had our own

marketing and designer hence we save a lot cost from marketing perspective, it

is more costly when entering new market (licensing, certification and listing).

We are tapping into online shopping platform like Taobao, Amazon and Walmart in

near future.

Plans to

improve OBM Bottomline

Currently no

profits and breaking even, it’s the tender business pulling the profits down,

for the last 25 years we are doing great in OEM and Tender but the trend is OBM

in the next 10 years, supermarkets are using discountal modal, which means

20,000 skus they are shrinking to 5,000 SKU’s only 2-3 brands of condom they

are allow in the supermarkets. We will not see any profit for the next 1-2

years from the OBM, for short term profit boost, maybe with our latex

operational efficiency, USD higher, Brent Oil are going down, Latex price are

sliding, more automation from our end, new ultra-thin products, we can produce

same 003 as okamoto, these might see our profit increase for short term. In

fact, only Karex is able to produce up to 60 sizes of condom while the others

are normally 3, with the ultra-thin production, we can sell up to USD 0.06c /

condom.

Any share

buyback plans for company? As seen some shareholder had done some share buy

back and some had also sold, can elaborate further on how CEO see about the

company future is it under or over value currently and with current price will

the company do some share buyback, also seen your cash is considerable.

We do not have

any share buyback plans in fact, most of the cash is for expansion plan as we

are still yet to utilizes, those funds will be mad at us why not using for

expansion but a share buyback.

How the company

spends the cash, there is significant decrease of 40m vs last year 86m?

Our yearly

capex is at approx. 20m a year, we spend on upgrading to automation and setting

new facilities like Thailand, Karex Polymer, our R&D a year is at 1.5-2m,

we paid dividends 0.05 cents, and we bought another 20% of global protection

for 7.5m, however we are still at healthy state as our company loans gearing

are at 0.07 which is super low, there is still a lot banks facilities which are

yet to be used, we have approx. 150m ready, and there is still 120m yet to be

used. Some of the cash are actually at inventory as there is 1 large shipment

is still at the ports awaiting government to check and will shipped out, this

also affect why our Q1 profits are less, because this shipment hasn’t been

shipped out. Karex results actually cannot be judge by quarterly Q1 and Q2

sales are normally higher, shipment delays do happen sometime due for

government checking and also because some government spends before year end

December when our financial end at June.

Side Information

-

Condom Material

Polyurethane – is less flexible than latex,

it’s going to be more prone to breakage

Polyisoprene – ultra-thin, allergy-free,

natural rubber, stretch much more, recover their original shape

after being stretched, soft

feeling.

Latex – Normal condom material

-

Results

Q1 (July-Sept) and Q2 (Oct-Dec) is higher

compare to Q3 (Jan-Mar) and Q4 (Apr-Jun), government normally buys before year

end December to utilize their remaining funds.

Karex results is not Recommend to view as

quarterly, due to timing of product listing, licensing, shipment and

certification.

-

Cost

/condom

Normal Condom USD 0.03

Ultra-Thin (0.035-0.039 millimeters) USD 0.06

-

Acquisitions

market

The company has made five acquisitions —

US-based Line One Laboratories Inc and the UK’s Pasante Healthcare Ltd, among

others, for US$8 million and £6 million (RM33.66 million) respectively.

These companies were bought not only for

the condom brands, but for their distribution advantages as well. For instance,

Pasante has a strong presence in retail and tender via its distribution system

in every National Health Service (NHS) in the UK.

“Distribution is very important. You need

to knock on their store and have a relationship with any particular NHS clinics

to buy products from them,” he said.

For Line One, Karex acquired intellectual

properties including the trademarks, patents and Food and Drug Administration

approvals to market and distribute condoms under the established brands of

Trustex, Kameleon and Fantasy in the US.

The company will buy the balanced 30% of

Global Protection Corporation before June 2020, they are suggesting share swap

in between.

-

Impressions

on CEO

CEO presented an impressive presentation

without any stress after results are declining for the past 1-2 years, in fact,

more than 3 shareholders actually praise his attitude, calmness and confidence

in his presentation to let shareholder know the company is in right track and

CEO knowing the company well.

文章只供参考,不构成买卖建议,买卖自负。